Servo Cylinder can replace the hydraulic cylinder and air cylinder completely and implement the environment greener and more energy efficient, more clean,

Easy connect to PLC control system , realize the high precision motion control!

Long life grease maintenance free

Turn down for more+

IMB Servo Electric Cylinder Performance Table:

| Model | IMB10 | IMB20 | IMB30 | IMB40 | IMB50 | IMB60 | IMB80 | |||||||||||

| Lead mm | 4 | 5 | 10 | 5 | 10 | 25 | 5 | 10 | 20 | 5 | 10 | 20 | 6 | 10 | 20 | 16 | 20 | 32 |

| Max Load N | 600 | 3500 | 3500 | 8500 | 8500 | 5000 | 18000 | 22000 | 12000 | 22000 | 45000 | 30000 | 30000 | 55000 | 60000 | 100000 | 150000 | 150000 |

| Max. Speed mm/s | 333 | 350 | 700 | 229 | 458 | 1145 | 142 | 283 | 567 | 112 | 225 | 450 | 105 | 175 | 350 | 226 | 283 | 453 |

| Torque max. Force Nm | 0.53 | 3.87 | 7.66 | 9.40 | 18.61 | 27.40 | 19.70 | 48.66 | 52.55 | 24.08 | 98.53 | 131.37 | 39.41 | 120.4 | 262.74 | 308.82 | 579.04 | 926.46 |

| Dynamic load Ball Screw KN | 4.7 | 7.6 | 7.5 | 12.7 | 17.4 | 10 | 23.2 | 29 | 15.8 | 26 | 55.6 | 45.7 | 34.2 | 62.4 | 90.8 | 200 | 305 | 305 |

| Parallel inertia kg㎡10-4 | 0.0415 | 0.552 | 0.575 | 1.286 | 1.351 | 1.426 | 7.079 | 7.482 | 9.186 | 78.739 | 78.913 | 79.609 | 82.452 | 82.793 | 83.545 | 196.664 | 200.613 | 205.236 |

| Inline inertia kg㎡10-4 | 0.0245 | 0.128 | 0.156 | 0.745 | 0.81 | 0.885 | 4.006 | 4.425 | 6.028 | 32.619 | 32.793 | 33.489 | 52.312 | 53.356 | 54.127/td> | 150.534 | 154.630 | 154.630 |

| Inertia/100mm kg㎡10-4 | 0.0165 | 0.0515 | 0.053 | 0.301 | 0.305 | 0.329 | 1.965 | 1.978 | 2.129 | 4.83 | 4.83 | 4.83 | 12.1 | 12.1 | 12.1 | 31.742 | 31.850 | 32.318 |

| Max. Stroke mm | 500 | 500 | 1000 | 1200 | 1500 | 2000 | 2500 | |||||||||||

| Max. input rpm | 5000rpm | 4200rpm | 2750rpm | 1700rpm | 1350rpm | 1050rpm | 850rpm | |||||||||||

| Max. Acceleration m/s2 | 3 | 3 | 6 | 3 | 6 | 10 | 3 | 6 | 10 | 3 | 6 | 10 | 3 | 6 | 10 | 3 | 6 | 10 |

| Weight(Without motor)kg | 5.3 | 7.9 | 18.2 | 29 | 76.9 | 126.3 | 132.6 | |||||||||||

| Weight per 100mm kg | 0.78 | 1.03 | 2.1 | 3.5 | 4.8 | 7.1 | 15 | |||||||||||

| SCREW TYPE |

IMB Series----Ball screw actuator ,100% duty cycle, long lifetime IMA Series----ACME screw actuator ,30% duty cycle, moderate lifetime IMR Series----Roller Screw actuator 100% duty cycle, very long lifetime, 15X of ball screw |

|||||||||||||||||

| Max.idling angle° | ±0.3 | ±0.3 | ±0.3 | ±0.25 | ±0.15 | ±0.15 | ±0.3 | |||||||||||

| Axial backlash mm | 0.02-0.04 | 0.02-0.04 | 0.02-0.04 | 0.02-0.04 | 0.02-0.04 | 0.03-0.05 | 0.03-0.05 | |||||||||||

| Lead error/300mm mm | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | 0.023 | 0.03 | |||||||||||

| Repeat accuracy mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 | |||||||||||

| CAD drawing download |  CAD drawing download CAD drawing download |

CAD drawing download CAD drawing download |

CAD drawing download CAD drawing download |

CAD drawing download CAD drawing download |

CAD drawing download CAD drawing download |

CAD drawing download CAD drawing download |

CAD drawing download CAD drawing download |

|||||||||||

Servo electric cylinder Coding

IMB series

DMB series

IMR series

IMA series

2

4

5

10

20

30

40

50

60

80

5

10

20

25

30

50

100

200

300

400

500

600

700

800

900

1000

Specical

FF----Front Flange

RF----Rear Flange

RC----Rear clevis

ST----Trunnion

SH----Side mount

SF----Side Flange

GM----Guide mountion

BA----Female thread

FM----Male thread

ROE---Rod end

TS----Ball joint

FO----Clevis end

FL----Flange end

TC----Bearing support

FZ----Anti-impact attachmen

NMT-Drive shaft Only

G05-Planetary gearing5:1 ratio

GX-Planetary gearing special ratio

SC-Inline with motor flange

P10-Parallel 1:1 ratio

P20-Parallel 2:1 ratio

AR---Anti-Rotate device

FCM--Magnetic reed switches

FCP--Inductive proximity switches

SP---Rear bracket

B----Bellow

PF---Pre-load

PL---Load Sensor

Lenze

Siemens

Yaskawa

Panasonic

Mitsubishi

FUJI

Other

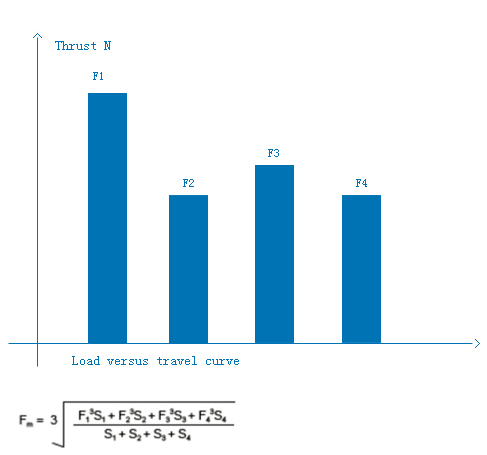

Expected Ball screw lifetime L10 is 90% of stroke ability that screw could reach before metal fatigue, Unit is million millimeters. The expected lifetime does not guarantee a lifetime. In order to reach max. Lifetime the screw needs been appropriate maintenance and lubricate.

95% :L10 x 62% 96% :L10 x 53% 97% :L10 x 44%

98% :L10 x 33% 99% :L10 x 21%

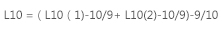

L10 : Expected Lifetime km

C : Rated Dynamic load N S:Screw Lead mm

L10(1)Extending direction expected lifetime, formula same as standard nut

L10(2)Retract direction expected lifetime , formula same as standard nut

In order to calculate accurate lifetime of ball screw, we need get cubic mean load.