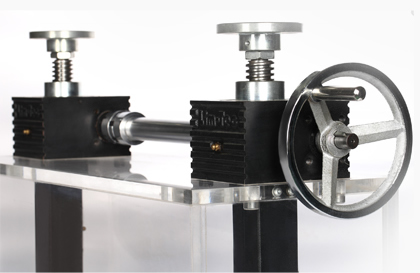

Advanced processing equipment and the assembly process is the assurance of high quality

Advanced design idea created impact resistant ability, high strength, low noise, long life,

Small volume of high quality products!

High precision movement, the steady movement, low noise, high speed

Turn down for more+

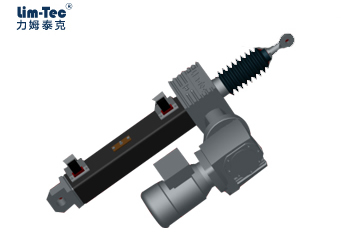

The principle of S type screw jack is worm drive worm wheel rotating , inside worm gear is the internal thread hole (engages with screw), then the rotary motion to screw to make linear motion.

The principle of R type screw jack is worm drive worm wheel rotating, worm gear connect screw fixed by key, so transfer rotary motion to the screw rotation movement, lead screw drive the nut up and down straight

Each type of screw jack can connect directly with ac motor/servo motor, stepper motor/explosion-proof motor by motor flange with coupling , but the motor power does not exceed the maximum allowed power of screw jack, standard motor as: ABB/WEG/ SEW/NORD!

Each type of screw jack can be directly connected to various AC geared motors through flange couplings, but the maximum input torque of the screw jack needs to be checked, and the minimum speed can be 5mm / min or lower. The gear motor can be helical gear motor, parallel output shaft gear motor, bevel gear motor, worm gear motor standard configuration is SEW / NORD / Siemens, etc.!

Acme Screw Screw Jack Parameter Table

| Type | SJA5 | SJA10 | SJA20 | SJA50 | SJA80 | SJA100 | SJA200 | SJA300 | SJA450 | SJA700 | SJA1000 | |

| Max lifting load [kN] | 5 | 10 | 20 | 50 | 80 | 100 | 200 | 300 | 450 | 700 | 1000 | |

| Screw dia x lead [mm] | Tr18x4 | Tr20x4 | Tr30x6 | Tr40x7 | Tr50x8 | Tr60x9 | Tr80x12 | Tr100x16 | Tr120x16 | Tr140x20 | Tr160x20 | |

| Worm ratio | V1 | 1:4 | 1:4 | 1:6 | 1:7 | 1:8 | 1:8 | 1:8.75 | 1:10.25 | 1:10.75 | 1:13.3 | 1:13.3 |

| L1 | 1:16 | 1:16 | 1:24 | 1:28 | 1:32 | 1:32 | 1:35 | 1:41 | 1:43 | 1:40 | 1:40 | |

| Stroke for one input turn [mm] | V1 | 1 | 1 | 1 | 1 | 1 | 1.125 | 1.371 | 1.56 | 1.49 | 1.5 | 1.5 |

| L1 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.281 | 0.343 | 0.39 | 0.37 | 0.5 | 0.5 | |

| Max input power [kW] | V1 | 0.30 | 0.57 | 0.14 | 2.2 | 2.5 | 3 | 4 | 7 | 11.5 | 18.5 | 22 |

| L1 | 0.15 | 0.27 | 0.55 | 1.1 | 1.5 | 2.2 | 3.5 | 5.5 | 5.5 | 7.5 | 9.5 | |

| Max starting torque at full load[Nm] | V1 | 4.2 | 8 | 18 | 48.5 | 75 | 100 | 265 | 460 | 675 | 1050 | 1620 |

| L1 | 1.5 | 3.1 | 6.7 | 20 | 30 | 41 | 106 | 180 | 275 | 510 | 820 | |

| Starting efficiency | V1 | 0.24 | 0.25 | 0.19 | 0.18 | 0.17 | 0.18 | 0.17 | 0.18 | 0.16 | 0.16 | 0.15 |

| L1 | 0.16 | 0.16 | 0.12 | 0.11 | 0.10 | 0.11 | 0.11 | 0.12 | 0.10 | 0.11 | 0.10 | |

| Running efficiency at 1500 rpm | V1 | 0.34 | 0.35 | 0.33 | 0.32 | 0.31 | 0.33 | 0.33 | 0.33 | 0.30 | 0.31 | 0.29 |

| L1 | 0.25 | 0.25 | 0.24 | 0.23 | 0.22 | 0.23 | 0.22 | 0.23 | 0.20 | 0.21 | 0.19 | |

| Torque without load[Nm] | V1 | 0.11 | 0.29 | 0.4 | 0.84 | 1.85 | 2.1 | 2.8 | 3.8 | 5.5 | 8.5 | 11 |

| L1 | 0.09 | 0.18 | 0.29 | 0.59 | 1.12 | 1.4 | 2.1 | 3.1 | 4.5 | 5.5 | 7.5 | |

| Housing material Weight[kg] |

Ductile iron | Cast steel | ||||||||||

| 3.2 | 5 | 8.5 | 21.5 | 36 | 58 | 75 | 110 | 200 | 400 | 800 | ||

| Weight per 100mm screw & protective tube[kg] | 0.36 | 0.50 | 0.75 | 1.52 | 2.44 | 3.02 | 4.5 | 6.8 | 9.0 | 12.5 | 16.5 | |

| Drawing Download |

click to download click to download

|

click to download click to download

|

click to download click to download

|

click to download click to download

|

||||||||

Lim-Tec provided complete system design and components, Which including screw jacks , motor, gear box, shaft, coupling , brake , clutch etc. Customer just need let us know your requirement of total load capacity, speed, stroke and dimension, Lim-Tec engineering will provideSJA Acme Screw Jack you a design scheme with calculation process and components selection, CAD drawing is also available.

Mature and reliable technology solutions will be your guarantee of safety equipment, please directly contact with local office sales engineer for concrete proposal!